In high-risk industrial environments, early fire detection can mean the difference between a minor incident and a catastrophic loss. The Det-Tronics Model HD Heat / Risk Area Detector is designed to provide reliable, rapid detection of abnormal temperature changes in hazardous areas, ensuring critical safety measures are activated before damage escalates.

Built for tough conditions and compliant with global safety standards, this detector is trusted in industries such as oil and gas, chemical processing, manufacturing, and power generation. In this guide, we’ll explore what makes the Det-Tronics Heat / Risk Area Detector a vital component of modern fire and gas detection systems, its key features, applications, and installation best practices.

Why Heat and Risk Area Detectors are Used in Industries

Industrial environments such as oil refineries, chemical plants, manufacturing facilities, and power stations operate with high temperatures, flammable materials, and complex processes. In these settings, the risk of fire or explosion is much higher than in standard workplaces. Heat and risk area detectors are essential safety devices that identify dangerous conditions before they escalate.

These detectors monitor temperature changes in critical zones, detecting both gradual and sudden increases that may signal overheating, equipment failure, or fire. Early warnings allow for quick actions such as activating alarms, shutting down equipment, or triggering fire suppression systems.

Their role is not only to prevent damage but also to protect lives, minimize downtime, comply with safety regulations, and safeguard valuable assets. In industries where every second counts, heat and risk area detectors provide a vital layer of protection against potentially devastating incidents.

Overview of the Det-Tronics Model HD Heat / Risk Area Detector

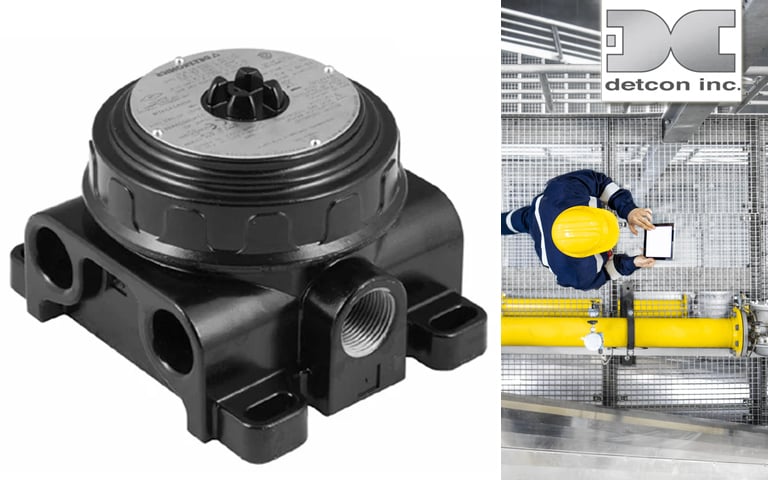

The Det-Tronics Model HD Heat / Risk Area Detector is a high-performance, rate-compensated heat detector designed for demanding industrial environments. It continuously monitors ambient air temperature and activates its electrical contact output when a preset temperature is reached. This precise actuation is made possible by the expansion properties of the metal alloys in its construction, ensuring reliable operation even under harsh conditions.

Engineered for versatility, the Model HD can serve as an alarm device to alert personnel of excessive heat or fire, or as a signaling unit that communicates with alarm panels to initiate fire suppression systems. Its rate compensation technology allows it to respond more effectively than conventional fixed-temperature or rate-of-rise detectors. Unlike rate-of-rise models, which can produce false alarms from normal process heat currents, or fixed-temperature units that may react too slowly to rapid fires, the Model HD offers a faster and more accurate response in critical situations.

Built to withstand extreme temperatures from -40°C to +125°C (-40°F to +257°F), the detector is available with an explosion-proof aluminum or stainless steel junction box. It supports 12-26 AWG (2.5-1.5 square millimetre) wiring and comes with three-quarter-inch NPT or M25 thread options. With IP66/67 and NEMA Type 4X ratings, as well as Zone 1, 2, and 21 approvals, it is well-suited for hazardous areas. The Model HD is also SIL 2 capable, meeting stringent safety integrity requirements for critical applications.

Key Features of the Det-Tronics Model HD Heat / Risk Area Detector

The Det-Tronics Model HD is engineered to provide reliable, high-performance heat detection in hazardous industrial environments. Its standout capabilities include:

- Fast detection

The Model HD delivers a quicker response than many traditional heat detection devices, helping identify fire or overheating conditions before they escalate. This rapid detection capability is critical in high-risk environments where every second can make a difference.

- Self-resetting design

After activation, the detector automatically resets itself without the need for replacement parts. This reduces maintenance downtime and ensures the device remains ready for the next potential hazard.

- Durable construction

Built to endure harsh industrial conditions, the Model HD withstands mechanical shock and constant vibration. Its robust design makes it ideal for facilities where equipment is exposed to challenging operating environments.

- Multiple temperature options

Available in a variety of temperature settings, the detector can be tailored to match specific process or safety requirements. This flexibility allows it to be used effectively across different industrial sectors.

- Cost-effective installation

The detector’s ability to be installed with wide spacing between units reduces the total number of devices needed. This lowers both material and labor costs during installation.

- Hermetically sealed contact

The internal contact area is factory-sealed within a stainless steel enclosure, protecting it from dust, moisture, and corrosive elements. This sealing ensures long-term reliability and consistent performance.

- Simple setup

Designed for ease of wiring and installation, the Model HD minimizes setup time for technicians. Its straightforward design helps ensure a smooth and efficient deployment.

Applications of the Det-Tronics Heat / Risk Area Detector

The Det-Tronics Heat / Risk Area Detector is built for high-risk industrial settings requiring precise heat and fire detection. Its rugged design, wide temperature range, and safety certifications make it ideal for use in industries such as:

- Oil and gas facilities

Ideal for drilling rigs, refineries, and gas processing plants where explosive gases and vapors may be present. The Zone 1 and Zone 2 ratings, along with an explosion-proof junction box, ensure reliable performance in these high-risk environments.

- Chemical and petrochemical plants

Performs reliably in areas with volatile chemicals and corrosive atmospheres. The stainless steel sensing element and hermetically sealed contact provide protection against chemical exposure.

- Power generation plants

Handles high heat conditions near boilers, turbines, and generators with an operating temperature range from minus forty to plus one hundred twenty-five degrees Celsius. Its rugged construction withstands continuous vibration common in power facilities.

- Mining operations

Operates effectively in environments with constant dust, vibration, and harsh mechanical stresses. IP66/67 and NEMA Type 4X ratings protect it from dust ingress and water penetration.

- Food and beverage manufacturing

Resists corrosion and damage from moisture, steam, and cleaning agents used in processing areas. The stainless steel housing and sealed internal components maintain performance in sanitary production environments.

- Marine and offshore platforms

Designed to endure salt-laden air, high humidity, and rough weather conditions. Its corrosion-resistant materials and hazardous area ratings make it dependable for offshore oil and gas operations.

- Grain handling and milling facilities

Certified for Zone 21 dust environments, allowing it to detect dangerous heat buildup in combustible dust atmospheres. The explosion-proof design ensures safe operation even in high-dust processing areas.

Get Det-Tronics flame and gas detectors from PE Energy

PE Energy is a trusted, authorized distributor of Det-Tronics products, ensuring you receive genuine equipment backed by manufacturer support. We offer competitive pricing on the Model HD, making it a cost-effective choice for industrial safety. For large-scale projects, we provide bulk supply options and consolidated shipping services to help reduce procurement costs and streamline delivery.

In addition to the Model HD Heat / Risk Area Detector, PE Energy supplies a wide range of Det-Tronics products to meet diverse safety needs. Whether you are looking for Det-Tronics X3302 Multispectrum Infrared Flame Detector, Det-Tronics X2200 UV Flame Detector, or Det-Tronics CGS Combustible Gas Sensor, PE Energy has the right solution for your application.

Contact PE Energy today for a competitive quote and take the next step toward enhancing the safety of your industrial environment.

Original Post Here: How Det-Tronics Model HD Heat / Risk Area Detectors Enhance Industrial Safety

No comments:

Post a Comment