When it comes to industrial safety, a gas leak is one risk you can't afford to ignore. Whether in oilfield operations, oil refineries, chemical plants, or wastewater facilities, even a small leak can lead to serious hazards. That's why companies around the world rely on the Detcon Model Series OLCT 700/710 industrial gas detection sensors.

These detectors don't just meet industry standards; they set the benchmark for reliable gas detection in tough environments. In this article, we'll dive into what makes the OLCT 700 and 710 trusted worldwide, highlight their standout features, and explore their applications across industries.

Why Fixed Gas Detection Sensors Are Used in Industries

Fixed gas detection systems are a cornerstone of industrial safety, especially in environments where hazardous gases can appear without warning. The key reasons industries rely on these systems include:

- Worker safety

Fixed gas detectors continuously monitor for hazardous gases such as hydrogen sulfide (H2S), methane, or carbon monoxide, alerting workers before concentrations become dangerous. This early warning prevents accidents and ensures employees in high-risk environments like drilling and production can work with confidence.

- Regulatory compliance

Industries such as oil and gas must comply with strict safety regulations that require continuous gas monitoring. Fixed detection systems help companies meet these standards, avoiding penalties while reinforcing a strong commitment to safety.

- Asset protection and operational continuity

Gas leaks can damage equipment, cause fires or explosions, and result in expensive downtime. By detecting issues early, fixed gas detectors safeguard assets and keep operations running smoothly.

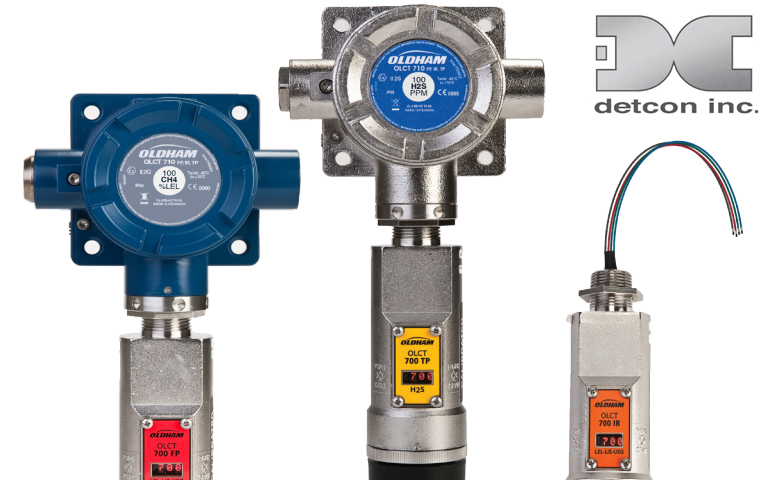

Overview of Detcon OLCT 700/710 Fixed Gas Detectors

The Detcon OLCT 700 and OLCT 710 are next-generation intelligent gas detectors designed for tough industrial environments. Built with an electropolished 316 stainless steel housing and fully encapsulated electronics, they offer superior protection against corrosion, water ingress, and electrical interference, making them highly reliable in extreme conditions.

Maintenance and operation are simple. Sensor elements are plug-in modules, allowing quick field replacement, while calibration and configuration are carried out non-intrusively with a handheld magnet. An intuitive menu system, displayed on the built-in LED screen, guides users through setup and routine checks.

For integration, both models provide dual outputs: a standard 4-20 mA analog signal and a Modbus RS-485 digital connection. Designed with Safety Integrity Level (SIL) compliance in mind, the OLCT 700/710 meet international standards such as IEC 61508 and IEC 61511, making them a dependable choice for critical industrial applications.

Key Features of Detcon OLCT 700/710 Fixed Gas Detectors

The Detcon OLCT 700 and OLCT 710 are designed with advanced features that make them highly reliable in demanding industrial environments. Below are some of their standout capabilities:

- Rugged stainless steel construction

Both models are built with electropolished 316 stainless steel housing, offering superior resistance to corrosion, chemicals, and harsh weather. This ensures long-term durability in extreme environments such as offshore platforms or chemical plants.

- IP66 environmental protection

The detectors are rated IP66, meaning they are dust-tight and resistant to powerful water jets. This level of protection makes them suitable for use in locations exposed to moisture, dirt, or extreme weather.

- Multi-layer surge protection

To guard against electrical disturbances, the Detcon OLCT 700/710 series feature multi-layer transient spike protection. This safeguards the internal electronics and ensures continuous, uninterrupted operation even in electrically noisy environments.

- Safety Integrity Level (SIL2) Certified

In line with IEC 61508 and IEC 61511 standards, the detectors meet SIL2 certification, proving their reliability in critical safety systems. This makes them a trusted component in high-integrity industrial safety designs.

- Environmentally resilient design

Often described as "environmentally bulletproof," these detectors are engineered to withstand corrosive atmospheres, water ingress, and other environmental challenges. Encapsulated electronics further protect them against damage, reducing the risk of failures.

- Dual output for system integration

Each detector provides both a 4-20 mA analog signal and a Modbus RS-485 digital output, ensuring easy integration into new or existing control systems. This flexibility supports a wide range of industrial applications.

- Easy maintenance and user-friendly interface

With plug-in sensor elements, field replacement is quick and straightforward. Calibration and configuration are non-intrusive, carried out using a handheld magnet and guided by clear instructions on the LED display.

Applications of Detcon OLCT 700/710 Fixed Gas Detectors

The versatility of the Detcon OLCT 700 and OLCT 710 makes them suitable for a wide range of industries where gas detection is critical. Below are some of the key applications where these detectors deliver dependable safety and performance:

- Oil and gas facilities

These detectors are ideal for offshore platforms, refineries, and gas processing plants where the risk of hydrocarbon leaks is high. Their rugged stainless steel housing and SIL2 certification ensure dependable performance in mission-critical environments.

- Chemical and petrochemical plants

In chemical production and storage areas, the Detcon OLCT 700/710 provide reliable monitoring of toxic and combustible gases. Their corrosion-resistant construction allows them to withstand exposure to aggressive chemicals and vapors.

- Wastewater treatment plants

The detectors effectively monitor hazardous gases such as methane and hydrogen sulfide that are common in wastewater operations. With IP66 protection, they remain operational even in humid and corrosive atmospheres.

- Power generation facilities

These sensors help safeguard workers and equipment in power plants where combustible gas leaks pose significant safety risks. Their dual output system ensures seamless integration with existing plant monitoring systems.

- Industrial manufacturing sites

From food processing to metal fabrication, the OLCT 700/710 can be deployed in a wide range of manufacturing processes. Their robust design and easy maintenance make them suitable for continuous monitoring in diverse industrial environments.

PE Energy is a Trusted Supplier of Detcon Products

PE Energy is an authorized supplier of the Detcon Model Series OLCT 700/710 industrial gas detection sensors. The company provides competitive pricing, consolidated shipping options, and flexible bulk supply solutions, making it easier for businesses to equip their facilities with reliable safety equipment without unnecessary delays or costs.

In addition to the Detcon OLCT 700/710 series, PE Energy supplies a broad range of Teledyne Detcon products. These include the DM-700 Toxic Gas Detector, the FP-700 Combustible Gas Sensor, and the TP-700 Hydrogen Sulfide Sensor, among others. Whether you need a single detector for a specific application or bulk units to secure an entire facility, PE Energy has the capability to meet your supply requirements efficiently.

For more details or to request a personalized quote, contact PE Energy today and take the next step in ensuring safety and protection for both people and assets in your industry.

Originally Published Here: Why the Detcon OLCT 700/710 Are Trusted Fixed Gas Detection Sensors

No comments:

Post a Comment